The measurement of force and pressure plays a vital role across numerous industrial sectors, from manufacturing and aerospace to healthcare and automotive engineering. Accurate force and pressure sensing is critical for ensuring process efficiency, product quality, and safety compliance. In recent years, with the development of smart manufacturing and IoT applications, force and pressure sensors have evolved significantly in terms of precision, stability, and integration.

These sensors can detect variables such as load, strain, torque, and pressure in real time, enabling automated control and intelligent feedback systems. They are widely used in equipment calibration, structural monitoring, robotic feedback systems, medical devices, and industrial automation. This article comprehensively introduces the main types of force and pressure sensors, their applications, and recommended solutions.

Why Force & Pressure Monitoring Requires Multiple Sensor Types?

The mechanical environment of industrial systems is complex, often involving dynamic loads, vibrations, and harsh conditions. No single sensor can comprehensively detect all aspects of force and pressure behavior. Instead, different types of sensors work together to provide a full picture of physical interactions:

- Force Sensor: Measures the direct force applied to an object; often used in robotic arms, testing machines, and process control systems.

- Load Cell: Specialized force sensor that converts mechanical force into an electrical signal; ideal for weighing systems, material testing, and safety monitoring.

- Pressure Sensor / Pressure Transducer: Measures pressure exerted by gases or liquids; widely used in HVAC systems, hydraulic and pneumatic control, and fluid dynamics.

- Strain Gauge Sensor: Measures deformation or strain in a material under stress; critical in structural monitoring and precision engineering.

- Torque Sensor: Measures rotational force or torque applied to a shaft or rotating system; important for motor testing, screwdriving tools, and mechanical power systems.

By combining these sensors in an integrated system, industries can achieve high-precision, real-time mechanical monitoring.

Main Sensor Types

Force Sensor

Force sensors detect mechanical force acting upon a surface. These sensors are essential for applications requiring feedback control, such as robotic gripping, product testing, and ergonomic evaluation. Advanced force sensors are compact, responsive, and capable of multi-axis force detection.

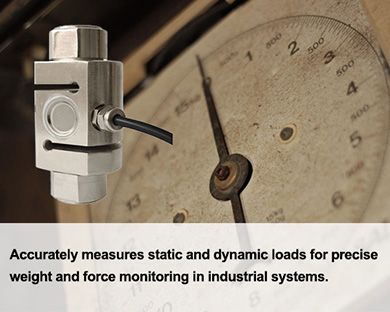

Load Cell

Load cells are highly accurate transducers that convert force into measurable electrical signals. Available in various types such as beam, S-type, and compression, they are the backbone of weighing systems in logistics, manufacturing, and structural load monitoring. Load cells often incorporate strain gauges and require precise calibration for accuracy.

Pressure Sensor / Pressure Transducer

Pressure sensors detect force per unit area exerted by liquids or gases. They are critical for monitoring pipelines, tanks, HVAC systems, and engines. Modern pressure sensors use piezoresistive, capacitive, or optical technologies and support analog or digital outputs, enabling easy integration into automated systems.

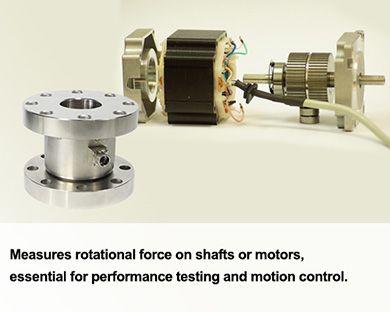

Torque Sensor

Torque sensors measure the rotational force on shafts or machinery. Widely used in engine testing, robotics, and tightening systems, torque sensors help ensure consistent mechanical performance and prevent overloading. They come in rotary and reaction types, often with integrated signal conditioning.

Strain Gauge Sensor

Strain gauge sensors measure the amount of strain or deformation experienced by an object under stress. These sensors are commonly bonded to structural components, allowing engineers to assess load distribution, fatigue, and safety margins. They are essential in aerospace, civil engineering, and materials testing.

Recommended Sensors Display

|

|

|

| Load Cell | Pressure Sensors | Torque Sensor |

Recommendation Reasons

Load Cells provide precise and stable measurements for static and dynamic load monitoring. They are widely adopted in industries like logistics, construction, and material science.

Pressure Sensors offer accurate monitoring of system pressure in fluid and gas circuits, ensuring safety and operational efficiency.

Torque Sensors are crucial in power transmission systems for measuring performance, wear, and overload protection.

Typical Industry Application Solutions

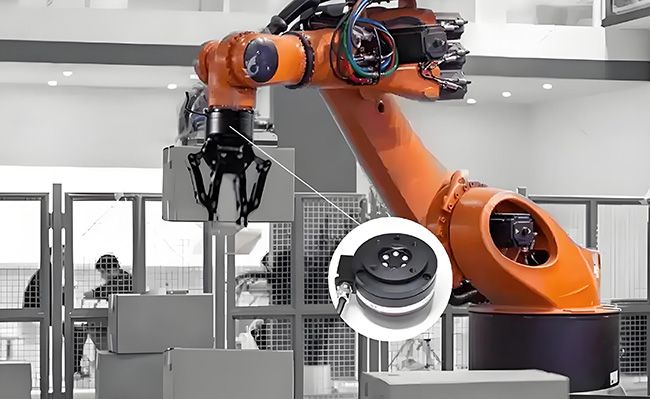

Industrial Machinery Load & Force Feedback System

In automated manufacturing, precise force control is critical to avoid product damage and improve quality. By installing force and load sensors on robotic end effectors and actuators, machines can adaptively adjust their behavior based on feedback.

Recommended Sensors:

- Force Sensor

- Load Cell

- Torque Sensor

| Sensor | Function Description |

| Force Sensor | Real-time feedback on pressing, gripping, or pushing force |

| Load Cell | Measures tool or platform load for safety control |

| Torque Sensor | Ensures correct torque in motors and drives |

Solution Suggestion: Deploy load cells and force sensors at key mechanical points, such as robotic arms, stamping units, and conveyor belts. Torque sensors can be used in motors or gearboxes to monitor load changes and prevent overload failures. Sensor data can be integrated into industrial IoT systems for real-time monitoring, predictive maintenance, and closed-loop optimization.

Structural Health Monitoring in Bridges & Buildings

Safety and maintenance of civil infrastructure require continuous monitoring of internal stress and load conditions. Strain and pressure sensors embedded in critical points help detect early deformation or failure risks.

Recommended Sensors:

- Strain Gauge Sensor

- Load Cell

- Pressure Transducer

| Sensor | Function Description |

| Strain Gauge | Monitors micro-deformation in structural components |

| Load Cell | Evaluates distributed load over large support beams |

| Pressure Sensor | Monitors hydraulic pressure in expansion joints or foundations |

Solution Suggestion: Install robust strain gauges and load cells at stress-prone locations such as beams, girders, and foundations. These sensors continuously measure load distribution, deformation, and stress accumulation. Pressure sensors embedded in shock absorbers or brackets track internal pressure changes caused by temperature or seismic activity. Data can be wirelessly transmitted to a centralized platform for risk assessment, maintenance planning, and early warning.

Automotive & Aerospace Testing Systems

Force and torque sensors are vital in testing vehicle components such as brakes, engines, and suspensions. These sensors ensure systems operate within safety margins under dynamic load conditions.

Recommended Sensors:

- Torque Sensor

- Force Sensor

- Strain Gauge Sensor

| Sensor | Function Description |

| Torque Sensor | Measures output of engines or electric motors |

| Force Sensor | Validates crash simulation and stress testing results |

| Strain Gauge | Tracks chassis or wing deformation during tests |

Solution Suggestion: Torque sensors on powertrains and dynamometers, along with force sensors in crash or impact zones, provide critical data during performance and safety testing. Strain gauges embedded in structural components help evaluate material fatigue and deformation. For dynamic testing environments, sensors should be connected to high-speed DAQ systems to ensure synchronized, accurate measurement and detailed analysis, supporting advanced design validation.

Force and pressure sensors are fundamental to the digital transformation of industrial and mechanical systems. Whether in robotics, automotive testing, structural safety, or medical innovation, these sensors provide reliable and actionable data that empower automation, safety, and intelligence. With modular design, real-time communication capabilities, and precision engineering, Such Online Store offers a complete range of sensor products to meet the demands of modern force and pressure monitoring.