Conductivity Sensor

Inductive Conductivity Sensor, 0~2000mS/cm

Industrial Conductivity Sensor, RS485/4-20mA

Conductivity Water Sensor, 4 Electrode

TDS Conductivity Sensor, 2 Electrode

Electrical Conductivity Sensor for Sewage, 0~130℃

Analog Electrical Conductivity Sensor, 4-20mA/0-5V/0-10V

Conductivity Probe, 0~2000μS/cm

Sanitary Conductivity Sensor, PFA, 1~2000mS/cm

Contacting Conductivity Sensor for Water, 0~5000μS/cm

Bluetooth Module for Conductivity Sensor

Conductivity Level Probe for Laboratory, 2~20000μScm

Inline Conductivity Sensor for Water, 0~200mS/cm

pH and Conductivity Sensor, 0~14pH, 0~10000μS/cm

Soil Electrical Conductivity Sensor, RS485/4-20mA/0-5/10V

Sanitary Conductivity Sensor, 0~130℃, 0~2000μS/cm

Water Quality EC Sensor, 0~20/0~200/0~5000 μS/cm

A conductivity sensor is an essential instrument designed to measure the electrical conductivity of a liquid solution, which directly reflects the concentration of dissolved ions. Since ionic concentration is a critical indicator of water purity, chemical concentration, or solution composition, conductivity sensors play a vital role in industrial production, laboratory research, and environmental monitoring.

Types

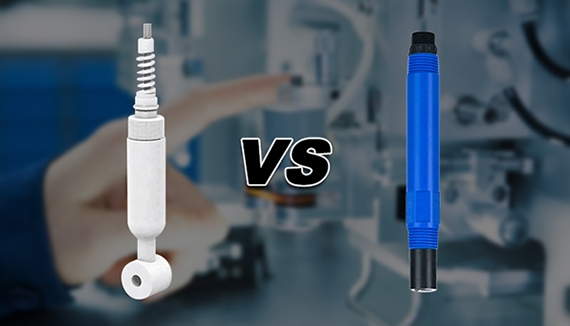

EC sensors are generally divided into two main categories: contact-type sensors and inductive (electromagnetic/non-contact) sensors.

- Contact-type sensors use electrodes made of graphite, stainless steel, or platinum to directly measure the conductivity of a solution. They are widely used in general water quality monitoring, such as in drinking water, cooling water, and wastewater treatment.

- Inductive conductivity sensors (also called toroidal or non-electrode sensors) measure conductivity through electromagnetic induction without requiring electrodes to directly contact the liquid. This makes them ideal for harsh environments such as strong acids, alkalis, or high-contamination solutions where electrode fouling is common.

Working Principle

Conductivity sensors measure the ability of a solution to conduct electricity, which depends on the concentration of ions present.

In contact-type sensors, an alternating voltage is applied across the electrodes, and the resulting current is measured. The current is proportional to the ionic concentration, allowing calculation of the conductivity.

In inductive sensors, a magnetic field is generated by a drive coil, inducing a current in the liquid. The magnitude of the induced current, detected by a secondary coil, corresponds to the solution’s conductivity.

Application Scenarios

Electrical conductivity sensor are widely used across multiple industries and research fields:

- Water treatment and environmental monitoring: measurement of boiler water, cooling water, reverse osmosis systems, seawater desalination, and wastewater discharge compliance.

- Agriculture and aquaculture: monitoring irrigation water, greenhouse hydroponic systems, and aquaculture pond quality to optimize growth conditions.

- Food and beverage industry: ensuring product consistency in beverages, dairy processing, and fermentation processes.

- Pharmaceutical and biotechnology industry: monitoring purified water and process liquids for compliance with strict quality standards.

- Chemical and semiconductor industries: used for acid, alkali, or chemical concentration monitoring, as well as ultrapure water measurement in semiconductor manufacturing.

Advantages

Conductivity sensors offer a range of significant advantages that make them essential in modern industrial and laboratory applications:

- High sensitivity and fast response: capable of detecting changes in ionic concentration in real-time.

- Wide measurement range: available in multiple ranges, from ultrapure water with very low conductivity to concentrated chemical solutions.

- Multiple output options: supports standard signals such as 4-20mA, 0-5V, 0-10V, and RS485/Modbus, ensuring compatibility with PLCs, DCS, and monitoring systems.

- Strong anti-interference performance: stable measurement even in noisy industrial environments.

- Durable construction: corrosion-resistant electrode materials or non-contact designs for extended service life.

- Low maintenance requirements: inductive types are less prone to fouling, making them suitable for continuous monitoring.

Other Features

Modern conductivity sensors often include automatic temperature compensation (ATC) to ensure accuracy across varying temperatures. Many SUCH conductivity sensor models also feature IP68-rated waterproof housings, allowing long-term immersion in harsh environments. For advanced applications, conductivity sensors can be integrated with IoT modules, enabling wireless data transmission and cloud-based monitoring. Customizable designs are available, ranging from portable pen-type conductivity testers for laboratories to robust online conductivity sensors for industrial plants.