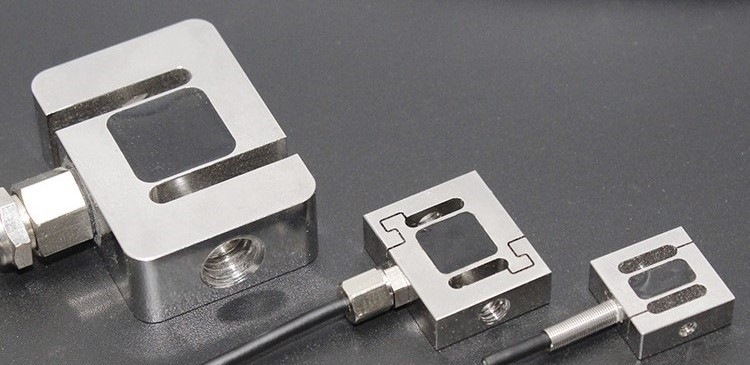

S Type Load Cell

S Shaped Load Cell, 1kg-7 ton

S Type Load Cell for Tension/Compression, 5kg-20 ton

S Beam Load Cell, 50kg-5 ton

Tension and Compression Load Cell, S Type, 200kg-5 ton

Micro Load Cell, S Type,1kg- 50kg

Miniature Load Cell for Tension/Compression, S Type,1kg-200kg

Factory direct sales of S type load cells. Shaped like the letter "S," these S type load cell sensors are force-measuring devices based on strain gauge technology. S type load sensors precisely quantify force by converting physical force (tensile or compressive) into a measurable electrical signal. The sensor core is crafted from a high-strength alloy, and its unique S-shaped structure ensures more uniform force transmission, ensuring accurate and reliable data output.

What Are The Features of S Type Load Cells?

- Bidirectional Force Measurement Capability: It supports both tensile force and pressure measurement at the same time, and can be adapted to different force scenarios without the need to replace the load cell, which makes it suitable for a wider range of applications.

- Structural Advantage: S-shape structure design makes the force transmission more direct and even, reduces stress concentration, and improves measurement accuracy and stability.

- Easy Installation: Both ends are designed with standard threaded holes for easy connection, compact size, strong overload resistance and easy to integrate into mechanical systems.

- Environmental Adaptability: Rugged structure, can resist dust, splash water attack, adapt to industrial workshops, outdoor and other harsh working environments.

What Are The Preferred Scenarios for S Type Load Cells?

- Systems that require simultaneous measurement of tension and compression, with frequent switching, such as material fatigue testing machines.

- Located installation space, especially limited radial dimensions, such as force feedback modules within equipment.

- Fast dynamic response is required when force changes rapidly, such as in impact loads and instantaneous tension adjustment.

- Environments subject to dust and splashing water, such as production lines in workshops and outdoor lifting, require certain protective measures.

How to Calibrate An S Type Load Cell?

- Confirm that the S type load cell sensor is correctly installed and securely fastened, without any looseness or offset. Use standard weights or calibration devices that meet the required range. Ensure a stable environment (temperature, humidity, electromagnetic interference, etc. can significantly affect the results).

- Disconnect the load and keep the S type load cell unloaded. Zero the display or meter to ensure that the output signal is zero when no load is applied. Load the S-type load cell with standard weights in increments (for example, 20%, 40%, 60%, 80%, and 100% of full scale) and record the difference between the S-type load cell output and the standard value. Check for linearity. If the deviation is significant, adjust the output. Remove the weights and observe whether the sensor output returns to zero to determine if there is hysteresis error.

- If there is any deviation, adjust the calibration parameters using the display controller, signal amplifier, or software. Repeat the loading/unloading process to confirm the accuracy of the calibration. Depending on the frequency of use and environmental conditions, calibration is recommended every 6-12 months. More frequent testing is required for applications requiring high precision.

When used with a digital indicator or transmitter, S type load cells form a complete weighing or force monitoring system. S type load cells can be integrated into automated production lines, laboratory test setups, or IoT-enabled monitoring platforms for real-time data acquisition and remote control. SUCH's technical team offers free selection consultation to ensure the sensor is the perfect fit for your application.