Strain Gauge

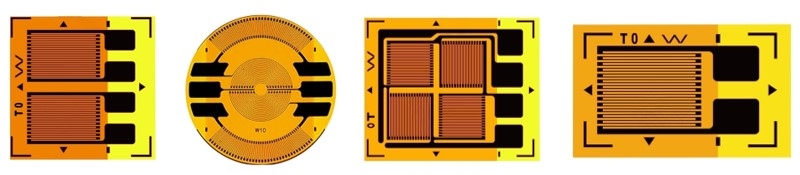

Half Bridge Foil Type Strain Gauge

Circular Diaphragm Strain Gauge

High Precision Full Bridge Strain Gauge

Half Bridge Shear Resistance Strain Gauge

Uniaxial Metal Foil Strain Gauge

Grid Type Resistance Strain Gauge

A strain gauge is a precision resistor element used to measure surface strain. It converts minute deformations of the structure being measured into measurable electrical signals, making it an essential sensor for mechanical testing and structural health monitoring.When an object undergoes slight deformation due to force, the strain gauge, tightly bonded to the surface, stretches or compresses the resistor material within it, causing subtle changes in resistance. By detecting these changes, the strain on the surface can be accurately determined, allowing the magnitude of the stress or load to be calculated.

Working Principle and Structural Features

A strain gauge typically consists of a metal foil, electrode leads, a substrate, and a protective layer. The metal foil is the primary sensing element, typically made of constantan, nickel-chromium alloy, or other materials with stable electrical resistance. It is etched into a fine grid structure to enhance sensitivity and stability. The substrate supports and secures the grid wires and ensures a good fit with the object being measured.

In actual measurements, a strain gauge is typically connected to a Wheatstone bridge circuit. When the object being measured deforms, the slight change in resistance causes a corresponding change in the bridge output voltage, thereby converting strain into an electrical signal. This method offers high accuracy and fast response, making it the most commonly used strain measurement method.

Types of Strain Gauges

Strain gauges come in a variety of types and can be categorized as follows based on their applications and characteristics:

Metal foil strain gauges: With a mature structure and stable performance, they are the most common type used in industry and scientific research.

Semiconductor strain gauges: Utilize the piezoresistive effect of semiconductor materials, they offer extremely high sensitivity but are significantly affected by temperature.

Shear strain gauges: Used to measure shear stress and torque, they are commonly used in force and torque sensors.

High-temperature strain gauges: Made of high-temperature-resistant materials, they can operate for extended periods at temperatures of hundreds or even thousands of degrees Celsius.

Encapsulated strain gauges: With a protective coating, they are suitable for environments with high humidity, high dust content, or corrosive environments.

Typical Applications of Strain Gauges

Strain gauges have a wide range of applications, covering nearly all areas requiring force, stress, or deformation measurement:

Engineering structure monitoring: Long-term safety monitoring of bridges, buildings, dams, and towers.

Machinery inspection: Assessing the stress conditions of mechanical components to prevent fatigue damage.

Sensor manufacturing: They are the core measuring elements of sensors for force, weight, pressure, and torque. Materials Testing and Research: Analyze the mechanical properties of metals, composites, plastics, etc.

Aerospace and Automotive Engineering: Used for structural testing, load verification, and vibration analysis.

Performance Characteristics and Technical Parameters

High-quality strain gauges feature high sensitivity, excellent linearity, stable temperature characteristics, and extremely low creep. Commonly used resistance values for strain gauge selection are 120Ω, 350Ω, and 1000Ω. Higher resistance values reduce power consumption and minimize measurement errors.

Fatigue life of strain gauges is also crucial. High-quality products can withstand tens of millions of strain cycles at room temperature without failure, which is particularly critical for long-term structural monitoring and dynamic load testing.

Installation and Usage Tips

The measurement accuracy of strain gauges is closely related to the quality of their installation. Before attaching, the surface to be measured should be cleaned, polished, and degreased to ensure a smooth and flat surface. Use a specialized adhesive to secure the strain gauge tightly, ensuring good stress transfer after curing. The leads should be secured gently, avoiding pulling to prevent false strain.

After installation, temperature compensation and zero point calibration are typically required. In environments with high humidity or strong corrosiveness, the surface of the strain gauge should also be protected from moisture, oil or chemicals to extend its service life.