Light Curtain

Infrared Light Curtain, 16/20/24/32/36 Beam

Photoelectric Light Curtain, 8/12/16/20/24 Beam

Safety Light Curtain Sensor for Guarding, NPN/PNP Output

Industrial Light Curtain, 8/12/16 to 24 Beam

Through Beam Safety Light Curtain, 6-32 Beam, NPN/PNP

Measuring Light Curtain, RS485/4-20mA/0-10V/NPN/PNP

Waterproof Safety Light Curtain, 4/8/10/12/20 Beam

Light Curtain Sensor, 4/8/10/16/18/22 Beam

Mini Safety Light Curtain, 4/6/12/16/18 Beam

Machine Guarding Light Curtain, 4-52 Beam, NPN/PNP

Diffuse Light Curtain, 4/6/12/22 to 28 Beam, NPN/PNP

Enhanced Safety Light Curtain, 14/16/24/32/34 Beam

Small Light Curtain, 6/8/10/20/30 Beam, NPN/PNP

Level 4 Safety Light Curtain, 16/20/28/30/34 Beam

Machine Safety Light Curtain, Side Light, 4-34 Beam

Standard Light Curtain, 4/14/24 to 32 Beam, NPN/PNP

The light curtain is a non-contact industrial safety device based on infrared beam detection technology, widely used for protecting hazardous areas in modern factories. Safety light curtains create a protective barrier through the coordinated operation of a transmitter and receiver. When a person or object enters the detection area, it quickly triggers a safety mechanism, cutting off the main control circuit of the equipment or issuing an alarm signal, preventing personal injury or equipment damage. Compared to traditional mechanical safety gates, SUCH safety light curtains reduce the workload of operators and significantly improve production efficiency, making them an ideal choice for your production safety protection.

Working Principle

Safety light curtain sensors operate based on the emission, reception, and signal processing of infrared light beams. The core components consist of a transmitter, receiver, controller, and related auxiliary components. The light curtain transmitter contains multiple infrared light-emitting diodes (LEDs) that emit modulated infrared light beams at a preset frequency and sequence. The light curtain receiver is equipped with the same number of photosensitive receivers, with each transmitter and receiver precisely aligned to form an independent light path, collectively creating a dense detection area. Under normal operating conditions, all infrared light beams successfully reach the receiver, the internal circuit outputs a low signal, and the equipment continues to operate normally.

When an object obstructs any of the light beams, the corresponding receiver cannot receive the modulated signal, and the circuit immediately outputs a high signal. The light curtain sensor controller then uses logic to send a stop signal to the safety relay or PLC, forcing the equipment to stop. To improve detection accuracy and resistance to interference, safety light curtains often employ pulse modulation technology to avoid ambient light interference. Simultaneously, redundant circuit design and self-diagnostic functions further ensure equipment reliability, allowing for real-time monitoring of beam alignment status, power supply abnormalities, and other issues.

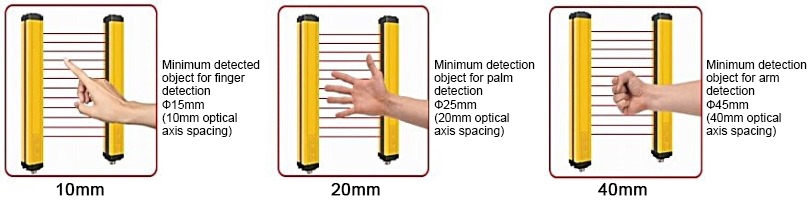

Differences in Optical Axis Spacing

10mm Optical Axis Spacing: Can detect small objects as small as 10mm (such as fingertips). Features high beam density and requires anti-interference design to cope with dust and strong light environments. Suitable for high-risk precision applications such as microelectronic equipment, medical machinery, and precision stamping machines, preventing injuries to small body parts.

20mm Optical Axis Spacing: Effectively detects hand or forearm intrusion, a common specification in industrial settings. Balances protection accuracy and environmental adaptability, working stably without complex anti-interference configurations. Suitable for medium-sized machinery protection, such as injection molding machines, press machines, and general stamping equipment.

40mm Optical Axis Spacing: Primarily protects larger body parts such as arms or torsos. Offers strong resistance to beam attenuation and high tolerance to environmental interference (vibration, dust). Suitable for large machinery and open areas, such as shearing machines, automated production lines, and robot enclosures, focusing on large-area safety interception.

Application Scenarios

- Mechanical Processing: Used as a safety light curtain in areas such as punch presses, shearing machines, bending machines, injection molding machines, and machine tool protection, immediately stopping the machine when operators approach dangerous areas to prevent finger, hand, or body injuries.

- Automation Assembly and Electronics Manufacturing: In automatic assembly lines, electronic component production, and SMT placement machines, measurement and detection light curtains are used for object positioning, part counting, size detection, and edge recognition, improving assembly accuracy and production efficiency.

- Packaging and Logistics Industry: Used in automatic packaging machines, sorting lines, and conveyor systems to detect product height, width, and position, for counting and classification, enabling automated sorting and quality control.

- Food and Pharmaceutical Industry: Used in filling lines, packaging lines, and production lines, combining safety protection and object detection to ensure operator safety while simultaneously performing product size and position detection. Waterproof light curtains are available for wet or cleaning environments.

- Robotics and Automated Handling: In industrial robot workstations and AGV automated handling systems, safety light curtain sensors prevent personnel from entering the robot's working range, improving workplace safety.