The optical industry is a high-precision field that relies heavily on advanced sensor technology to maintain accuracy, improve automation and ensure product quality. From lens manufacturing to laser applications and optical fiber, various types of sensors play a key role in optimizing production and inspection processes. As a key component of the optical system, various types of optical sensors are like sharp eyes that give devices the ability to perceive changes in light signals. SUCH online store will focus on sensors used in the optical industry, explore their characteristics in depth, and recommend related products and solutions.

Sensors used in the optical industry

Color Sensor:

Color sensors are based on the principle of RGB or spectral analysis. By capturing the spectral information of the light reflected by the object, the color sensor can accurately identify and distinguish the color. The color sensor can be used in conjunction with the automatic control system of the instrument to detect the color, color blocks and color lines as well as the existence of objects, and can realize automatic positioning, color recognition, correction, registration, counting and other functions.

Fiber Optic Sensor:

The fiber optic sensor transmits the optical signal from the light source to the modulator through the optical fiber, so that the measured parameter interacts with the light entering the modulation area, causing the optical properties of the light (such as light intensity, wavelength, frequency, phase, polarization state, etc.) to change. Then, the changed modulated signal source is transmitted to the optical detector through the optical fiber, and the measured parameter is obtained after demodulation. It has the advantages of anti-electromagnetic interference, high temperature resistance, corrosion resistance, etc., and can adapt to complex and harsh environments. It is an ideal choice for monitoring strain, temperature and pressure in optical systems.

Flame Sensor:

The flame sensor can quickly determine the presence of flames by detecting infrared, ultraviolet or visible light radiation generated by flames. In the process of optical coating or certain laser processing, the flame or plasma state needs to be precisely controlled to ensure the consistency of film quality. Such sensors can provide a fast response for process control.

Infrared (IR) Sensor:

Infrared sensors use infrared radiation emitted or reflected by the object itself for detection to sense the target temperature or position. Infrared sensors are widely used in infrared lens testing, thermal imaging calibration, non-contact temperature measurement and other scenarios, and are indispensable in the study of thermal stability and quality control of optical devices.

Image Sensor:

Image sensor converts optical images into electrical or digital signals and is the core component of digital cameras, surveillance cameras and other equipment. Image sensors can perform appearance inspection, dimension measurement, and image acquisition on products. They can be integrated into high-speed cameras and quality inspection systems to ensure surface defect detection and dimension measurement.

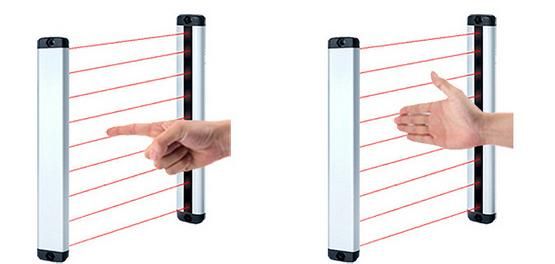

Light Curtain/Light Curtain Sensor:

The light curtain sensor consists of a transmitter and a receiver, which form one or more light curtains by emitting and receiving infrared beams. When an object blocks the light curtain, the sensor will respond immediately. Light curtain sensors are used for safety protection of automated optical machinery and for detecting the presence of components on assembly lines.

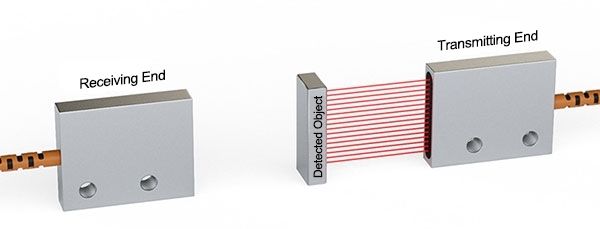

Photoelectric Sensor:

Photoelectric sensors include various types such as through-beam and reflective types. They determine the presence, position or state of an object by detecting the presence or absence of light or changes in intensity. Photoelectric sensors are often used for position detection, counting and object existence verification during the assembly process of optical equipment.

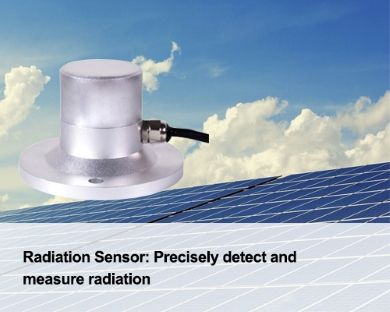

Radiation Sensor:

Radiation sensor is a type of sensor used to detect and measure electromagnetic radiation. It can sense radiation energy within a specific band, such as ultraviolet light, visible light, infrared light, and even X-rays and gamma rays. Radiation sensors are mainly used to monitor the radiation response of optical components, evaluate the transmittance or reflectivity of materials, calibrate the intensity of light sources, and evaluate the impact of light radiation in the environment on sensitive components.

Ultraviolet (UV) Sensor:

UV sensors work by sensing the intensity of ultraviolet radiation. UV sensors are used in lens production to monitor the ultraviolet curing process, verify ultraviolet sterilization, and control exposure, or to detect ultraviolet intensity and provide data for sun protection index evaluation.

Recommended sensors display

Radiation Sensor: Radiation sensors can sensitively sense radiation energy within a specific band, such as ultraviolet light, visible light, infrared light, and even X-rays and gamma rays.

Light Curtain: The light curtain constructs a non-contact safety barrier through an array of infrared beams. It can adjust the resolution (beam spacing) and detection range to adapt to different equipment sizes, taking into account both safety and production efficiency.

UV Sensor: The UV sensor provides real-time feedback of UV dose and is packaged with UV-resistant aging materials to adapt to outdoor or high-radiation environments, ensuring long-term measurement accuracy.

|

|

|

| Radiation Sensor | Light Curtain | UV Sensor |

Typical industry application solutions

Quality visual inspection system

How to achieve fast, accurate and reliable quality inspection has always been a core issue of concern to manufacturing companies. Traditional manual inspection has low efficiency and large errors, and it is difficult to meet the stringent requirements of high-speed assembly lines, while simple inspection devices cannot identify complex defects or make detailed judgments.

- Solution Recommendation

In response to this problem, it is recommended to use the image sensors, photoelectric sensors and light curtain sensors to jointly build a stable and high-performance quality visual inspection system. These three types of sensors have their own advantages and complement each other, and can meet industrial inspection needs from multiple dimensions such as image acquisition, target recognition, position judgment and size detection.

- Recommended Sensors

| Sensor | Recommended reason |

| Image sensor | Appearance inspection, size measurement and image acquisition of products. |

| Photoelectric sensor | Determine the existence, position or state of an object by detecting the presence or absence of light or changes in light intensity. |

| Light curtain sensor | Used for safety protection and detection of the presence of components on the assembly line. |

The image sensors, photoelectric sensors and light curtain sensors provided by SUCH online store are easy to install and highly compatible, and are suitable for various production line automation equipment. Combined with actual working conditions and industry needs, users can choose models with different resolutions, response speeds and detection distances to quickly build a suitable personalized quality inspection system.

High-temperature environment monitoring and flame control

In the optical industry and special material processing, high-temperature environment monitoring and flame control have always been key factors affecting safety and product quality. The existence of flames, the distribution of high-temperature heat sources, and changes in the radiation intensity of light sources may have a significant impact on product molding effects and equipment safety. Traditional detection methods are often slow to respond, have a small coverage area, or cannot be remotely monitored, making it difficult to meet high-precision and high-stability production requirements.

- Solution Recommendation

A high-temperature and flame monitoring solution that integrates flame sensors, infrared sensors, radiation sensors, and ultraviolet (UV) sensors recommended by SUCH can achieve all-around detection of high-temperature areas, combustion states, and energy radiation.

- Recommended Sensors

| Sensor | Recommended reason |

| Flame sensor | Real-time monitoring of gas burning status, quick judgment of the presence of flame. |

| Infrared sensor | Non-contact temperature measurement, feedback of local or overall temperature changes. |

| Radiation sensor | Effective monitoring when direct temperature measurement is not possible. |

| Ultraviolet sensor | Sensing ultraviolet radiation intensity, ensuring UV is within the appropriate range. |

By integrating the high-temperature environment monitoring and flame control built by the above multiple sensors, light can achieve more accurate energy control and more stable processing while ensuring safety. The flame, infrared, radiation and UV sensors provided by Such sensor shop have stable performance and can be applied to different fields.

Color detection and calibration

In the high-precision manufacturing and testing process, color calibration and color consistency detection are key links to ensure product performance and visual effects. Due to the influence of factors such as light source and material, color may deviate and need to be calibrated and tested. Manual detection is not only inefficient and poorly repeatable, but also difficult to meet the needs of industrial batch control.

- Solution Recommendation

It is recommended to use the relevant high-performance sensor products provided by SUCH, including color sensors, image sensors and fiber optic sensors. These optical sensors form a color detection and calibration system, which measures the displayed color in real time and compares it with the preset standard color. The display parameters are adjusted through the feedback control system to achieve color calibration.

- Recommended Sensors

| Sensor | Recommended reason |

| Color sensor | Achieve accurate recognition and distinction of colors. |

| Image sensor | Capture color distribution, defect location, and texture differences. |

| Fiber optic sensor | Collect the measured light, avoid interference, and improve coupling accuracy. |

By integrating color sensors, image sensors and fiber optic sensors to form a practical color detection and calibration solution, SUCH's solution can help optical companies achieve accurate, efficient and intelligent color calibration and detection tasks on automated production lines, significantly reduce human errors and improve product consistency.