In the field of motion and position, sensors are needed to detect key parameters such as the position, speed, acceleration and direction of objects to ensure the accuracy and stability of system operation. These sensors are components that convert changes in non-electrical quantities (such as speed and pressure) into changes in electrical quantities. They are parts and accessories for measuring and controlling instruments and equipment. The highly sensitive sensors provided by SUCH online shopping platform are widely used in automation equipment, robots, logistics and transportation systems, and intelligent transportation systems to achieve position tracking, path control and posture adjustment, and improve overall efficiency and safety.

Sensors related to motion and position

Acceleration Sensor:

Acceleration sensors are used to detect the acceleration of objects and are widely used in motion control and posture perception. Acceleration sensors have a fast response speed and high sensitivity. Depending on the different sensitive elements of the sensor, common acceleration sensors include capacitive, inductive, strain, piezoresistive, piezoelectric, etc.

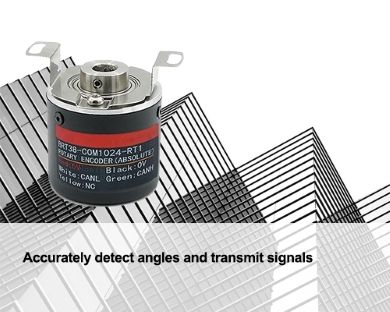

Encoder:

An encoder is a device that compiles and converts signals (such as bit streams) or data into signal forms that can be used for communication, transmission and storage. Encoders are used to measure rotational or linear displacement and output accurate position, speed or direction signals. Its advantages are high resolution and durability.

Gyroscope Sensor:

A gyroscope sensor can sense angular velocity and is often used to measure heading, attitude or rotation. It is a simple and easy-to-use positioning system based on free space movement and gestures. Its advantages are strong anti-interference and strong stability.

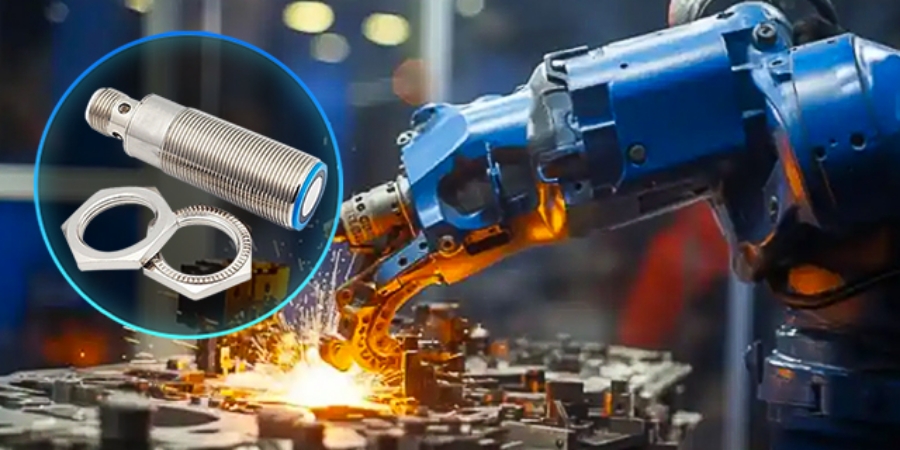

Proximity Sensor:

A proximity sensor is a sensor that detects objects without contacting them. It can detect the movement and existence information of the object and is suitable for metal or non-metallic objects. It has a fast response and long life, and is widely used in object detection, limit and safety protection.

Sonar Sensor:

Sonar sensor is an electronic device that detects the distance of an object by emitting sound wave signals and receiving reflected echoes. It is suitable for underwater detection and robot obstacle avoidance. Its advantages are strong penetration and wide adaptability to the environment.

Ultrasonic Sensor/Ultrasonic Transducer:

Ultrasonic sensors are sensors that convert ultrasonic signals into other energy signals (usually electrical signals). Ultrasonic sensors use the principle of ultrasonic reflection to measure distance or liquid level. They have the characteristics of non-contact and high precision. They are suitable for occasions such as distance measurement, obstacle avoidance and liquid level control.

Vibration Sensor:

A vibration sensor can sense the vibration amplitude and frequency of the structure or equipment, and is often used for equipment operation status monitoring and fault warning. It is sensitive to response and has good stability, and is a powerful tool for industrial equipment maintenance.

Recommended sensors

Acceleration sensor: The Acceleration sensor is used to detect the movement speed and acceleration changes of objects in real time, accurately identify speed and direction changes, fast response, small size, very suitable for dynamic posture tracking, and is a key component for analyzing the dynamic behavior of the human body or equipment.

Encoder: The Encoder is a detector that can output angle data within one rotation of the motor to an external target. The encoder compiles and converts signals or data into signal forms that can be used for communication, transmission and storage, with high resolution and extremely strong repeatability.

Proximity sensor: Non-contact detection, fast response, long life, can stably sense the approach or departure of the target. It can determine whether the object is in place without contact, which is suitable for judging the completion of the action and detecting the boundaries of the training range, and has stable and reliable performance.

|

|

|

| Acceleration Sensor | Encoder | Proximity Sensor |

Industry solutions

Industrial robot movement and position monitoring solution

Industrial robots have extremely high requirements for the high-sensitivity motion and position sensors in assembly, welding, handling and other scenarios. The traditional method that relies on program paths is prone to position offset, abnormal vibration and other problems due to load changes or unexpected interference, affecting product quality and equipment life. Therefore, robots need a set of sensor systems with high response and strong dynamic detection capabilities for real-time action and status monitoring.

- Recommended Sensors

| Sensor | Recommended reason |

| Acceleration sensor | Acceleration sensor is used to sense the acceleration change of the robot in real time and monitor dynamic processes such as starting, stopping and sharp turns. |

| Gyroscope sensor | The gyroscope sensor senses the robot's posture change and rotational angular velocity, and can stably control the robot's direction and posture in complex movements. |

| Vibration sensor | The vibration sensor monitors the robot's tiny vibrations or abnormal impacts during operation to ensure long-term stable operation of the robot. |

- Solution Recommendation

Acceleration sensors are integrated in the robot's end effector and joints, which can detect changes in acceleration, tilt and sudden movements in real time, helping the system to adjust the control logic in real time to maintain balance and smooth operation. Gyroscope sensors are used to track the rotation posture and direction of each axis, especially in multi-degree-of-freedom collaborative robots to ensure posture stability and path accuracy. Vibration sensors are installed in key bearing parts or support structures to monitor abnormal vibration and displacement, and issue maintenance warnings in time to avoid equipment damage caused by unbalanced movement. These three sensors build a system with dynamic judgment capabilities, allowing industrial robots to maintain high precision and high stability in high-load, continuous motion or complex trajectory operations, effectively extending service life and reducing maintenance costs.

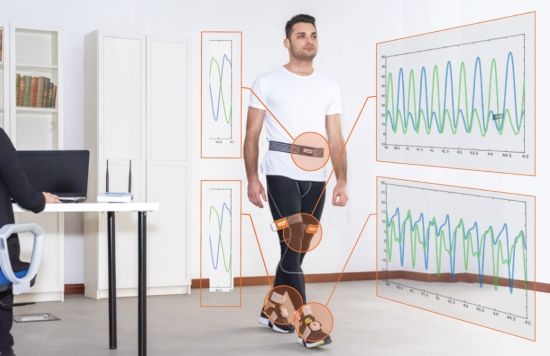

Human motion monitoring solutions for training

In the fields of rehabilitation medicine and intelligent sports training, accurate monitoring of human movements has become a rigid demand. Especially in limb movement training, how to obtain body posture and movement trajectory in real time, monitor the quality of movement completion, and prevent abnormal risks is directly related to training results and user safety. However, traditional reliance on manual observation or a single measurement method is often inefficient, with large errors, and it is difficult to monitor in real time in daily environments.

- Recommended Sensors

| Sensor | Recommended reason |

| Acceleration sensor | An acceleration sensor is used to monitor the speed and rhythm of limb movements, and to identify movement frequency and acceleration changes in real time. |

| Gyroscope sensor | Gyroscope sensor captures the rotation angle and posture changes of various parts of the body, and assists in evaluating the stability and symmetry of movements. |

| Encoder | The encoder is deployed on the active parts of training equipment to accurately measure angle changes and training times, and is used to quantify movement progress. |

- Solution Recommendation

During training, users can sense the direction, speed and posture of the movement in real time by wearing a module containing an acceleration sensor and a gyroscope sensor. With the high-precision encoder integrated inside the training device, the angle and frequency of limb bending, extension or rotation are automatically recorded to determine whether the movement meets the standard or whether there is any deviation. Based on these three types of sensors, movement amplitude curves, posture change trend charts and training frequency statistics can be generated to assist users in correcting their movements. This solution is suitable for scenarios such as repeated movement training for rehabilitation patients, intensive training for specific movements for athletes, and monitoring of daily exercise habits for the elderly.

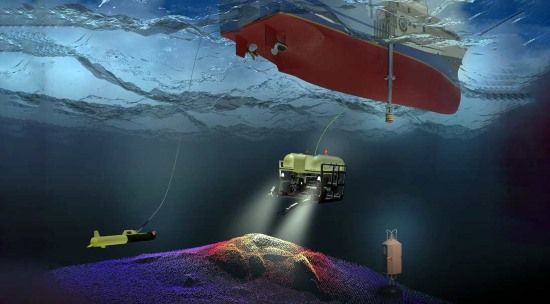

Underwater machine obstacle avoidance system

Underwater machines often face challenges such as low visibility, multiple obstacles and water disturbance when operating in complex waters, such as submarine cable detection, underwater equipment maintenance or marine scientific research tasks. Traditional visual navigation or GPS positioning is difficult to achieve underwater, and it is necessary to rely on multiple sensor fusion to build a reliable motion perception and obstacle avoidance system.

- Recommended Sensors

| Sensor | Recommended reason |

| Sonar sensor | Perform environmental perception, detect underwater obstacles and measure distance to avoid obstacles. |

| Gyroscope sensor | Real-time monitoring of heading changes, maintaining attitude stability, and preventing yaw or drift. |

| Acceleration sensor | Monitor acceleration and deceleration movements, identify sudden water disturbances or dynamic changes during the robot's start/stop process. |

- Solution Recommendation

Sonar sensors are deployed at the front and side of the machine to collect surrounding obstacle data in real time and feed it back to the control unit. Gyroscope sensors are used to continuously monitor underwater attitudes, provide pitch, roll and yaw angle data, and prevent attitude loss during diving or turning. At the same time, the acceleration sensor helps determine whether the robot is disturbed by sudden external forces (water flow impact, structural collision, etc.), and quickly makes motion adjustments to improve the overall running stability.